Introduction

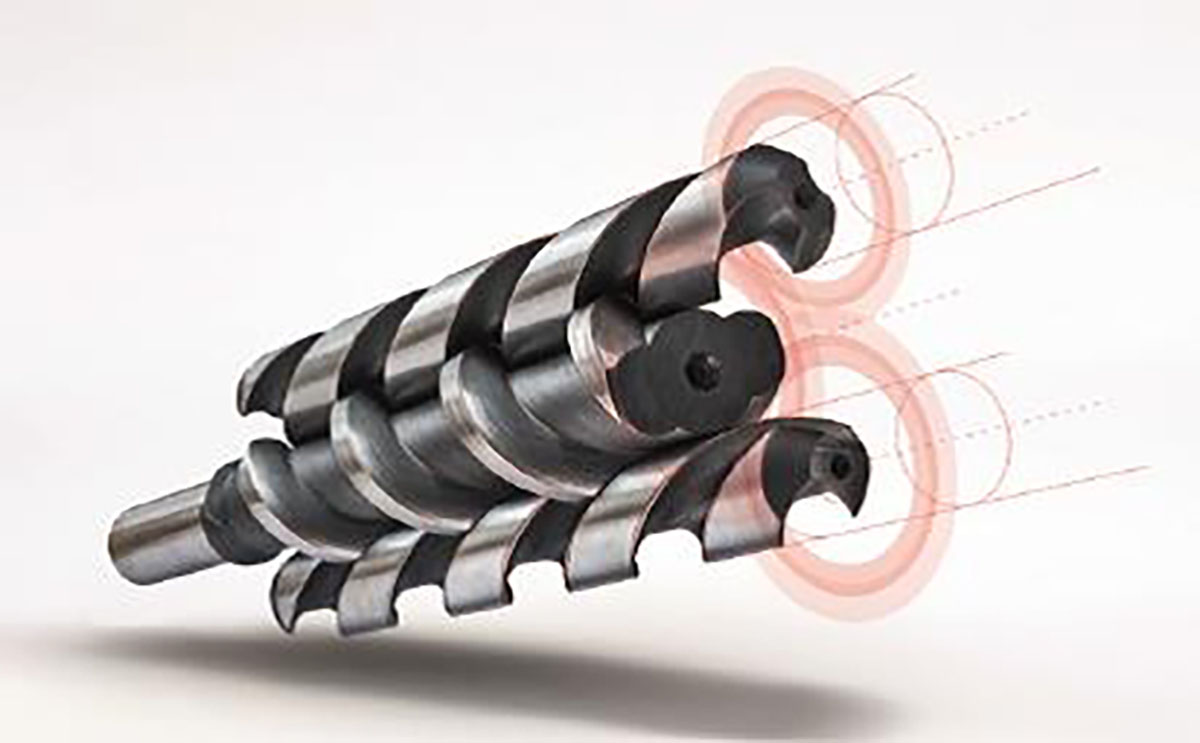

Spindle screw pumps feature a simple construction that offers high reliability, performance and efficiency for liquid cooling systems. Comprised of a single rotor element that is powered, while two others are idle, spindle screw pumps move fluid axially without turbulence, eliminating foaming that would otherwise occur in viscous fluids. The idle rotors are rotated by liquid pressure, essentially generating a fluid bearing, or hydrodynamic film, that provides radial support similar to journal bearings.

Spindle screw pumps move fluids of higher viscosity without losing flow rate, and pressure changes have little impact on spindle screw pumps This is important in a rotating application, such as a CT gantry system used in a CT scanner, as the pump is able to maintain constant flow and pressure while under high stress caused by high g-forces.

One of the most critical components in a liquid cooling system is the pump. Pumps are in constant operation when the unit is turned on and typically have the shortest mean time between failure (MTBF) of all components due to friction wear of bearings, pump blades and seals. If poorly chosen, the pump will fail prematurely and the liquid cooling system will fail and cause the end instrument to stop working. This can be a problem for expensive medical, laser or semiconductor equipment where hundreds of thousands of dollars could be lost per day. Compared to centrifugal pumps, spindle screw pumps provide higher reliability, performance and efficiency for liquid cooling systems.

Types of Pumps

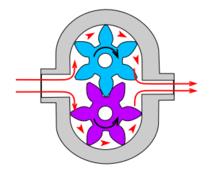

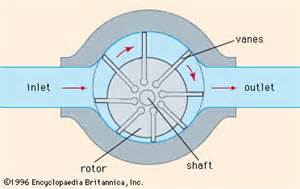

Many different types of pumps are available for liquid cooling systems, which can make it difficult choosing the appropriate pump. Each configuration has its own advantage and disadvantage when compared to each another. Positive-displacement pumps like gear pumps, rotary pumps, vane pumps or centrifugal pumps are the most common types of pumps available for medical, industrial laser or semiconductor use. They are cost-effective but can have shorter operating lifetimes and tend to be noisier. Typical operating life is about 9,000 hours.

Gear Pump

Rotary Pump

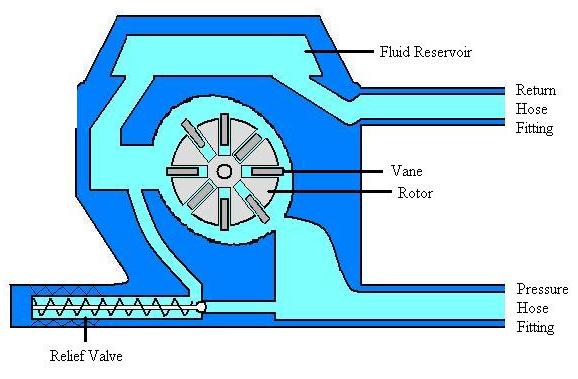

Vane Pump

Centrifugal Pump

Motors

Designing a liquid cooling system requires specifying the pump head and motor, which is typically sold separately for larger flow rates. Pump performance can be impacted by the motor size, as a poor performing pump head will require a stronger motor. As a result, the motor will be larger, heavier, louder and consume more power than necessary. Another problem that arises from this is the additional heat generated by the larger motor will transfer to the pump and coolant. This will drop the cooling capacity and make the liquid cooling system work harder to compensate for the additional heat transfer losses. Most motors run on AC power due the lower cost of eliminating a universal power supply. Single-phase AC motors are well established and are typically cheaper than three phase AC motors, but are also bigger and less efficient.

Failure Modes

Internal mechanical components limit the pump’s operating lifetime because of friction wear. Customers have to replace the pump after reaching a defined MTBF, which is typically 12K hours. This will result in higher service and maintenance costs which are often over looked at time of purchase.

To get the best performance in terms of pressure and flow rate, the tolerances of the mechanical components have to be very precise. For example, the gear pump is a high precision machine with extremely tight fits and tolerances. At a minimum, metal to metal contact is a given for moving parts inside the pump. This can create problems of high friction and abrasion. To reduce friction wear particles contained inside the coolant require a low mesh strainer. This will prevent large particle sizes from entering the narrow clearance tolerances and damage the mechanical components inside the pump. Cavitation, the sudden formation of low pressure bubbles, can also reduce lifetime, generate higher noise and lower pressure drop.

Other Issues

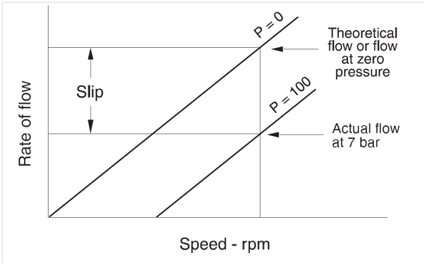

Most pump types do not self-prime, i.e. push coolant through pump from initial start without being gravity fed by coolant. Therefore, the pump needs to be located below the tank reservoir. Most pump types also pulsate when pushing coolant through a liquid circuit, which can be unusable for higher end applications. Pulsations will cause disturbances to maintaining peak performance and also increases vibration, which reduces operational life of a high-end system. To get the best performance and efficiency of a pump, tight tolerances of internal moving parts are required. The tighter the tolerance the better the performance, but this also increases noise and motor performance requirements due to the increase in friction. The tighter clearance of the working parts inside a gear pump are what enable it to efficiently pump coolants in high pressure environments. Low viscosity coolants such as water with glycol or other solvents have more of a tendency to “slip” through these tight clearances due to the higher-pressure discharge side of the pump back to the lower-pressure suction side of the pump. The phenomenon of slip causes a reduction in flow rate and pump efficiency.

Slip is a characteristic of positive displacement pumps and is defined as the quantity of fluid that leaks through internal clearances of a pump per unit of time. It is dependent upon the internal clearances, the differential pressure, the characteristics of the fluid handled, and, in some cases, the speed.

Vane pumps or centrifugal pumps have problems with cavitation. Based on mechanical design, cavitation causes higher noise level and reduced flow rates and operation lifetime. To compensate for this, a separate bypass coolant circuit is required, which results in cause higher costs and assembly.

Screw Pump

A screw pump is a positive displacement pump that uses one or several screws to move material along the screw(s) axis. In its simplest form, a single screw rotates in a cylindrical cavity, thereby moving liquids and/or solids along the screw's spindle. The screw pump is an old technique typically used in lower tech applications, such as irrigation systems and in agricultural machinery for transporting grain and other solids.

Spindle Screw Pump

Spindle screw pumps also have a simple construction. A three-screw pump, for example, features a single rotor element that is powered, while two others are idle. The idle rotors are rotated by liquid pressure, essentially generating a fluid bearing, or hydrodynamic film, that provides radial support similar to journal bearings. Symmetrical pressure loading on the power rotor eliminates the need for radial bearings to absorb radial forces.

The pump head and motor are combined into one waterproof housing unit and can push either oil or water coolant. The fluid delivered by a screw pump does not rotate, but moves linearly. The rotors work like endless pistons, which continuously move forward. Flow through a screw pump is axial and in the direction of the power rotor. The inlet hydraulic coolant that surrounds the spindles is trapped as the spindles rotate. The coolant is pushed uniformly with the rotation of the spindles along the axis and is forced out the other end. Due to this the power consumption is reduced, higher efficiency is achieved and the overall motor size can be reduced. This also enables the spindle screw pump to move fluids of higher viscosity without losing flow rate, and pressure changes have little impact on spindle screw pumps This is important in a rotating application, such as a CT gantry system used in a CT scanner, as the pump is able to maintain constant flow and pressure while under high stress caused by high g-forces.

Long life operation is built into the spindle screw design due to no metal-to-metal contact between moving components. This minimizes friction wear and abrasions that can cause cavitation. The flexible mechanical assembly allows the use of a smaller strainer with higher mesh size that extends maintenance intervals and reduces the overall cost of ownership. No metal-to-metal contact also results in the elimination of pulsations, even at high flow rates, making the unit very quiet during operation. The end result is smooth and quiet operation even at high revolution rates and pressure.

Spindle screw technology is ideally suited for liquid cooling systems in environments that require low noise conditions, such as imaging systems for patient modeling.

A spindle screw pump combines the most important attributes into one high reliable unit.

- Compact design

- High efficiency

- High capacity with little space

- High G force robustness

- High pressure and flow rates

- Long life time operation

- Low noise

- No pulsation

- No maintenance

- Pumping without violent turbulence

- Adjustable flow rate

Self-priming spindle screw pumps

Self-priming spindle screw pumps allow an independent flexible positioning within the liquid cooling system. Respective to the cost of ownership the value of highly reliable spindle screw pump is thru high lifetime operation that can span over several years with minimal to no maintenance. This minimizes down time by eliminating the need to turn off the end user system for pump replacement.

| Attributes | Positive Displacement (Gear, Vane, Rotary) | Centrifugal Pump | Spindle Pump |

| Max. Viscosity (cSt) | 1,320,000 | 550 | 150,000 |

| Max. Capacity (m³/min) | 750 | 27,250 | 3,550 |

| Energy Costs | Excellent | Average | Excellent |

| Self-Priming | Yes | No | Yes |

| Flow Control | Excellent | Poor | Excellent |

| Life-Cycle Cost | Good | Good | Very Good |

| Initial Cost | Average | Excellent | Average |

| Pumping Efficiency | Excellent | Average | Excellent |

| Noise Level | Medium | High | Low |

| Performance | Good | Poor | Excellent |

Conclusion

Compared to centrifugal pumps, spindle screw pumps offer many advantages including moving fluid axially without turbulence, which eliminates foaming that would otherwise occur in viscous fluids. Spindle screw pumps are also able to pump fluids of higher viscosity without losing flow rate. In addition, pressure changes have little impact on spindle screw pumps, making them ideal for a wide range of applications. Spindle screw pumps provide more consistent, reliable and efficient performance in liquid cooling systems.