Introduction

Medical lasers are designed for use in hospitals, outpatient surgical centers, and physician offices. They combine cutting, ablation, and coagulation properties for precise, virtually bloodless procedures; minimizing thermal damage to the surrounding tissue and increasing recovery time. They also sanitize the area through the heat of the laser, destroying any microbiological bodies that could lead to infection. Although medical lasers are valuable to many medical treatment applications, they do generate waste heat that affects the lasers performance when in operation. Manufacturers also face thermal management design challenges such as temperature stability, noise restrictions, space constraints, and reduced power consumption.

Medical lasers generate a large amount of heat that needs to be dissipated away from the sensitive laser components.

Application Cooling Requirements

Lasers generate a significant amount of waste heat that can affect peak performance of the laser. Heat generated by the laser can range from as little as 5 Watts to more than 150 Watts depending on the medical laser application. For optimal performance, the laser requires a stable operating temperature of 20°C ± 0.5°C, while ambient temperature may fluctuate in room temperature environment.

The thermal stability is particularly challenging because of form factor restrictions of the medical laser. Miniaturization of handheld lasers has led engineers to pack more electronics into a smaller footprint. More electronics increases functionality, like combining skin cooling with skin treatment, however, it also increases the complexity of the thermal solution. As a result, the thermal components must provide advanced thermal control, sometimes with multiple cooling loops and route heat dissipation thru tight geometric space constraints. As this is a handheld device, components must also be able to withstand shock and vibration to ensure long-life operation. To further reduce operating costs, low maintenance thermal management solutions are preferred.

In addition to cooling the laser, the patient’s superficial layers of the skin are typically cooled to protect the epidermis and prevent thermal injury. Cooling can be achieved by cold contact cooling, blowing cold air or cryogen spray (dynamic) cooling. Contact cooling is considered the best method for cooling skin. More sophisticated laser systems feature an imbedded contact cooling device to reduce pain and erythema to increase patient comfort during the procedure.

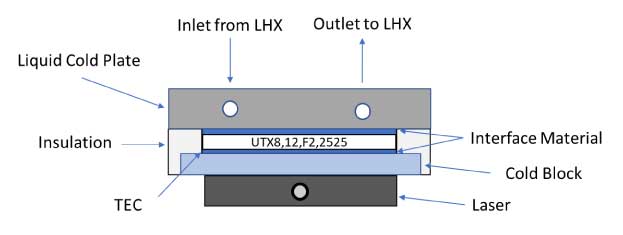

Below is an illustration of how a typical thermoelectric cooler is used to cool a medical laser. The thermoelectric cooler is mounted between two heat exchangers. On the cold side, a cold block is used with interface material to connect to the thermoelectric cooler. The cold block is then mechanically fastened to the laser. Due to space constraints, a liquid heat exchanger is typically used on the hot side to route heat out to ambient environment. Insulation is used to prevent moisture condensation into the thermoelectric cooler cavity and insulate heat transfer from the hot to the cold side.

Thermoelectric Coolers

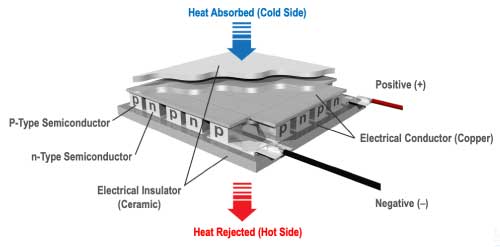

Thermoelectric coolers are solid-state heat pumps that require a heat exchanger to dissipate heat via the Peltier effect. During operation, DC current flows through the thermoelectric cooler to create heat transfer and a temperature differential across the ceramic surfaces, causing one side of the thermoelectric cooler to be cold, while the other side is hot. A single-stage thermoelectric cooler can achieve temperature differentials of up to 70°C and transfer heat at a rate of up to 150 Watts. In order to increase the amount of heat pumping capacity, the thermoelectric cooler’s modular design allows for the use of multiple thermoelectric coolers mounted side-by-side, which is called a TE array.

Thermoelectric coolers are composed of two ceramic substrates that serve as electrically insulating materials and house P-type and N-type semiconductor elements. Heat is absorbed at the cold junction by electrons as they pass from a low-energy level in the P-type element onto a higher energy level in the N-type element. At the hot junction, energy is expelled to a thermal sink as electrons move from a high-energy element to a lower-energy element.

Reversing the polarity changes the direction of heat transfer. Thermoelectric coolers are rated at maximum parameters (ΔTmax, Imax, Vmax, and Qmax) under no load conditions, with temperature control accuracy achieving ±0.01°C under steady-state conditions. They can cool to -100°C (6-stage) and pump up to 15 watts per centimeter square of heat, with higher heat pumping capacities achieved by wiring thermoelectric coolers into an array. Their geometry can vary from 2x2 mm to 62x62 mm and are much more efficient in heating mode than resistant heaters. They also fit into tight geometric space constraints and can be mounted in any orientation that cannot accommodate a much larger compressor-based system. Thermoelectric coolers offer high reliability, no operational noises and perform well in high-vibration applications such as medical lasers.

Laird Thermal Systems’ Ceramic Plate (CP) Series is a rugged, compact thermoelectric cooler designed for higher current and large heat-pumping applications like handheld cosmetic lasers. Placed next to the laser, the CP Series direct-to-air configuration offers a maximum cooling power of up to 120 Watts with a temperature differential (ΔT) of 70°C in a small form factor of 62 mm x 62 mm x 4.6 mm or smaller. The CP Series is available in a wide range of heat pumping capacities, geometric shapes, and input power ranges to meet handheld laser requirements.

Laird Thermal Systems CP Series offers a cooling power of up to 120 Watts.

With a heat pumping capacity of up to 299 Watts, the UltraTEC™ UTX Series thermoelectric cooler prevents medical laser systems from overheating. The UltraTEC UTX Series cooler utilizes advanced thermoelectric materials offering a 10% boost in heat pumping capacity compared to standard thermoelectric coolers. It also features a higher thermal insulation barrier creating a maximum temperature differential ΔT of 72°C. The UltraTEC UTX Series thermoelectric cooler not only offers high heat pump density, but precise temperature control to within ± 0.01°C.

Laird Thermal Systems UltraTEC UTX Series pumps between 69 and 299 Watts of heat.

Thermoelectric Cooler Assemblies

Thermoelectric cooler assemblies are cooling and heating systems that utilizes thermoelectric coolers to transfer heat by air, liquid or conduction methods that include integrated temperature control. Thermoelectric coolers remove the passive heat load generated by the ambient environment in order to stabilize the temperature of sensitive components used in medical lasers.

Thermoelectric cooler assemblies deliver precise temperature control in an efficient, stable, reliable, maintenance-free and compact form factor compared to other technologies such as compressor-based systems. In addition, thermoelectric cooler assemblies are environmentally friendly, as they do not use any refrigerants. Featuring solid-state construction with no moving parts, thermoelectric cooler assemblies operate reliably at low power with a low heat load and no noise – all in a small footprint. Because thermoelectric cooler assemblies can be mounted in any operation, they offer great integration flexibility.

Laird Thermal Systems’ Tunnel, PowerCool and SuperCool Series are specifically designed to suit cooling requirements in medical laser applications.

The SuperCool Series features a unique patented design that offers a high-performance hot side heat sink which dissipates heat more quickly and more efficiently than competing heat exchanger technologies, enhancing the cooling performance by up to 90%. The units operate on 24 VDC and are available in Air-to-Air, Direct-to-Air and Liquid-to-Air configurations with heat pumping capacities ranging from 110 to 407 Watts. Their smaller form factor design utilizes custom thermoelectric coolers to maximize cooling capacity and premium grade fans to minimize noise, while superior moisture-resistant insulation prevents condensation from penetrating into the chamber cavity.

The new SLA-400 SuperCool Thermoelectric Cooler Assembly offers the largest cooling capacity in the industry for its size. Liquid-to-Air units such as SLA-400 offer great flexibility because it can be mounted where space is available while cooling both the laser and the patient eliminating the need for separate cooling loops. This frees up space for other critical electronics resulting in a more compact medical laser system with maximum cooling capacity.

The SuperCool Series thermoelectric cooler assemblies ranges from 110 to 407 W and is offered in Air-to-Air, Direct-to-Air and Liquid-to-Air versions.

The PowerCool Series offers cooling capacities from 20 to 280 W. They are available in Air-to-Air and Direct-to-Air configurations that use impingement flow to dissipate heat on the hot side. The Air-to-Air assemblies cool objects via convection, where the heat is absorbed and dissipated by heat exchangers equipped with fans and ducted shrouds.

The PowerCool Series is offered in Air-to-Air and Direct-to-Air versions, ranging from 20 to 280 W.

The Tunnel Series uses a patented, high performance cross flow technology that maximizes heat transfer when pulling air through a heat exchanger. This cross-flow technology reduces the number of required airflow paths when compared to traditional impingement flow assemblies. The heat pumping action is generated by thermoelectric coolers, which are custom designed to achieve a high coefficient of performance to minimize power consumption. The smaller form factor Tunnel Series offers cooling capacities exceeding 100W to support a wide range of cooling applications. The Tunnel Series is offered in 12 or 24 VDC configurations and can cool by either convection (Air-to-Air) or conduction (Direct-to-Air) means.

The Tunnel Series thermoelectric cooler assemblies offers a cooling capacity from 10 to 100 Watts and is available in Air-to-Air and Direct-to-Air.

Conclusion

Thermoelectric coolers and assemblies are the preferred solution to temperature stabilize medical laser systems to maintain their peak performance. Through the Peltier effect, thermoelectric coolers deliver reliable solid-state operation with low maintenance requirements offering a low total cost of ownership. Thermoelectrics have compact form factors allowing them to accommodate the latest medical laser designs where space constraints can be an issue. They have enough cooling power to cool multiple components in a laser system simplifying the overall cooling solution. This cannot be accomplished by any other means without a complex heating and cooling system.

More information on the SuperCool Series can be found by visiting https://www.lairdthermal.com/products/product-series/supercool-series

More information on the PowerCool Series can be found at

https://www.lairdthermal.com/products/thermoelectric-cooler-assemblies/peltier-power-cool-series

More information on the Tunnel Series can be found at

https://www.lairdthermal.com/products/product-series/tunnel-series