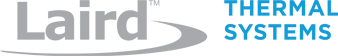

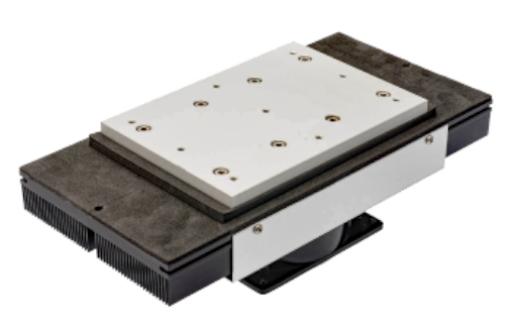

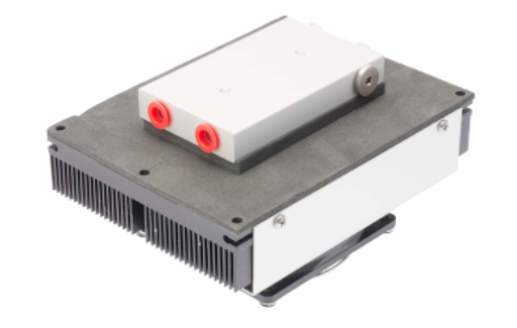

Thermoelectric Cooler Assemblies

Laird Thermal Systems offers the industry’s widest selection of thermoelectric cooler assemblies. With the ability to cool well below ambient, our thermoelectric cooler assemblies protect electronics inside enclosures from outside contaminants, and also limit moisture exposure from the outside environment. Offering precise temperature control, our thermoelectric cooler assemblies are designed to meet the cooling needs of many thermal management applications in the medical, analytical, industrial and telecom markets.